capsule filling machine working principle

In terms of production automation it is divided into the semi-automatic filling. If you choose an automatic system it will be handy for viscous materials as it comes with.

Automatic Capsule Filling Machine Njp Series Working Principle Ipharmachine

They also have a sealing rubber-cap-plate a lever and a cam handle.

. By creating the FEC40 Fette Compacting has proven its innovative capabilities regard to the industrial capsule filling. Working Principles of Various Filling Machines 1. Most encapsulating machines use either the tamping pin or dosator technology.

You can then process the Softgel capsules further by drying polishing or printing. It has 9 holes turning out a highest output of 1200 capsulesminute. Leading manufacturer on high quality and good accuracy machine.

The powder packaging machine needs to know. Below is an image showing how a dosator capsule filling machines works Ill explain this shortly. In a certain proportion after 7080 C low temperature cycle mixing and melting after a period of time the gelatin is vacuumed.

In stock ready to ship. These are the most crucial parts of a capsule filling machine. Rent buy or lease Filling Capsule Equipment Machines.

NJP Series fully automatic hard capsule filling machine varies its output by varying die assembly quantity of die hole. Ad Leading manufacturer of filling and capping machine in China with advanced technology. Working Principle of Dosator Type Capsule Filling Machine to Filling.

The capsule filling machine working principle is usually a very simple and straightforward process. The working principle of a cream filling machine includes. It is mainly used in the large scale production of capsules.

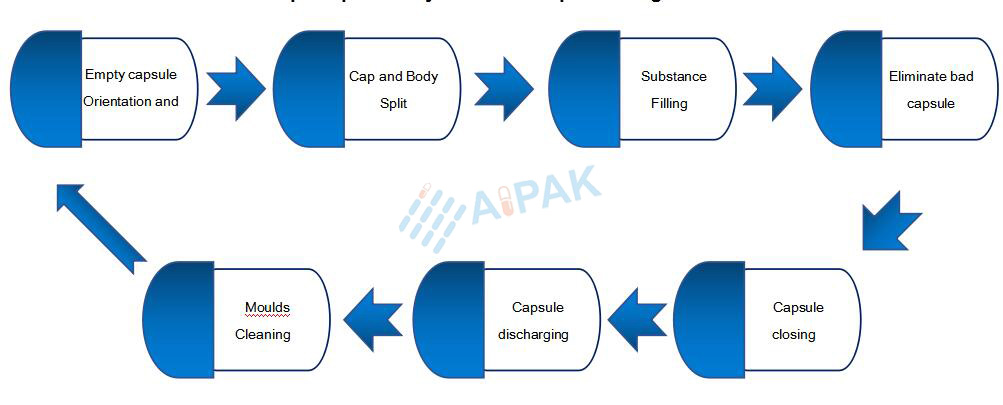

Httpswwwcapsulemachinesin demostrating Capsule Filling Machine Working Principal which shows Functional Principle of Capsule Filling Process. Automatic capsule filling machine is a fully automatic capsule filling machine with which capsule separation filling and locking can be done automatically. But how does a process like this wor.

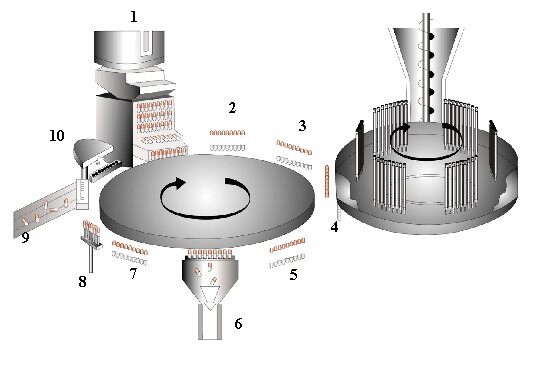

Check the power supply and electrical control switches every day to see if other parts are safe and reliable and check the working conditions of each part whether there are abnormal phenomena or unusual sounds etc. The trays can hold many capsules at a time to make the process fast. During the intermittent capsule filling machine the movement of the capsule is dependent on the partition box for continuous dis continuous rotation The filling volume of the capsule is mainly determined by the volume of the measuring disc hole.

The body of the capsule is transferred to the filling station where. This is usually considered as the best capsule filling machine. The liquid filling machine works when the pressure is high.

The filling machine is mainly a small type of product in the packaging machine. Automatic capsule filling machine working principle. In most machines empty capsules and place in trays a bottom and top tray.

The working principle of soft gelatin capsule filling machine involves preparing gelatin fill material preparation and actual encapsulation process. During the operation the capsules in the charging hopper at the first station are fed through two hoppers vertically to capsule-feeding plate one by one. Ad Browse discover thousands of brands.

Ad Quality Capsule Filling Machine with Competitive Price. Liquid Filling Machine Its Principles. - Thursday June 6 2019.

Trusted China Suppliers Verified by SGS. Custom Made is acceptable. The concept of operation for gas filling machines is relatively simple.

The ointment filling machine uses a volumetric method to measure the contents with precision. The working principle of the filling machine. This is the working principle of our common small powder automatic packaging machine.

Principles of operation of gas filling machines. Over 5000 happy customers. From the perspective of packaging materials it can be divided into liquid filling machines paste filling machines powder filling machines and particle filling machines.

The machine that can greatly improve production efficiency and reduce labor costs. This is usually because of the maximum convenience that it provides. Working principle of soft capsule filling machine and operation method Oct 07 2019 Soft capsule filling machine through pre-treatment integrated ingredients adding pure water solid particle medical bone gelatin additives vitamins glycerin etc.

Automatic Capsule filling machine. The automatic capsule filling machine is the one thats designed and developed to fill the capsules automatically. These personal capsule filler machines allow people to fill their capsules with the necessary medication.

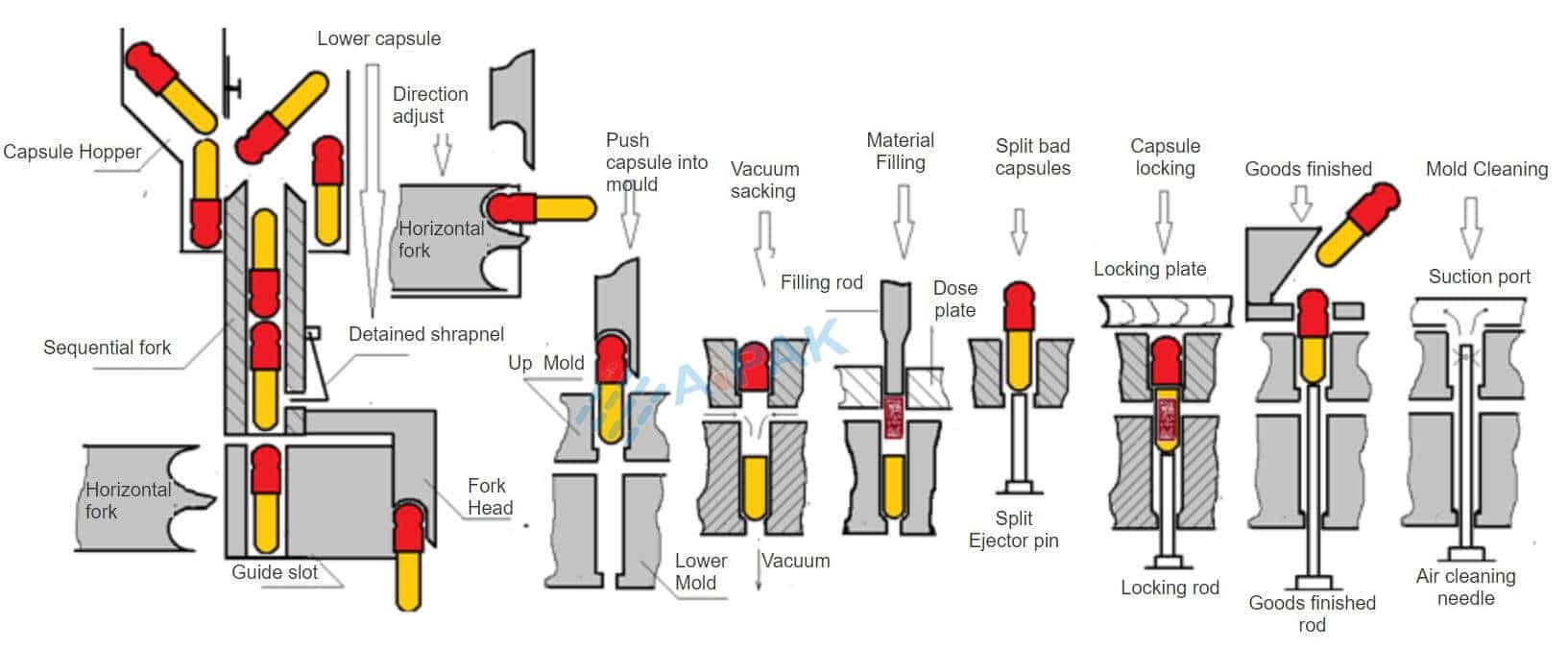

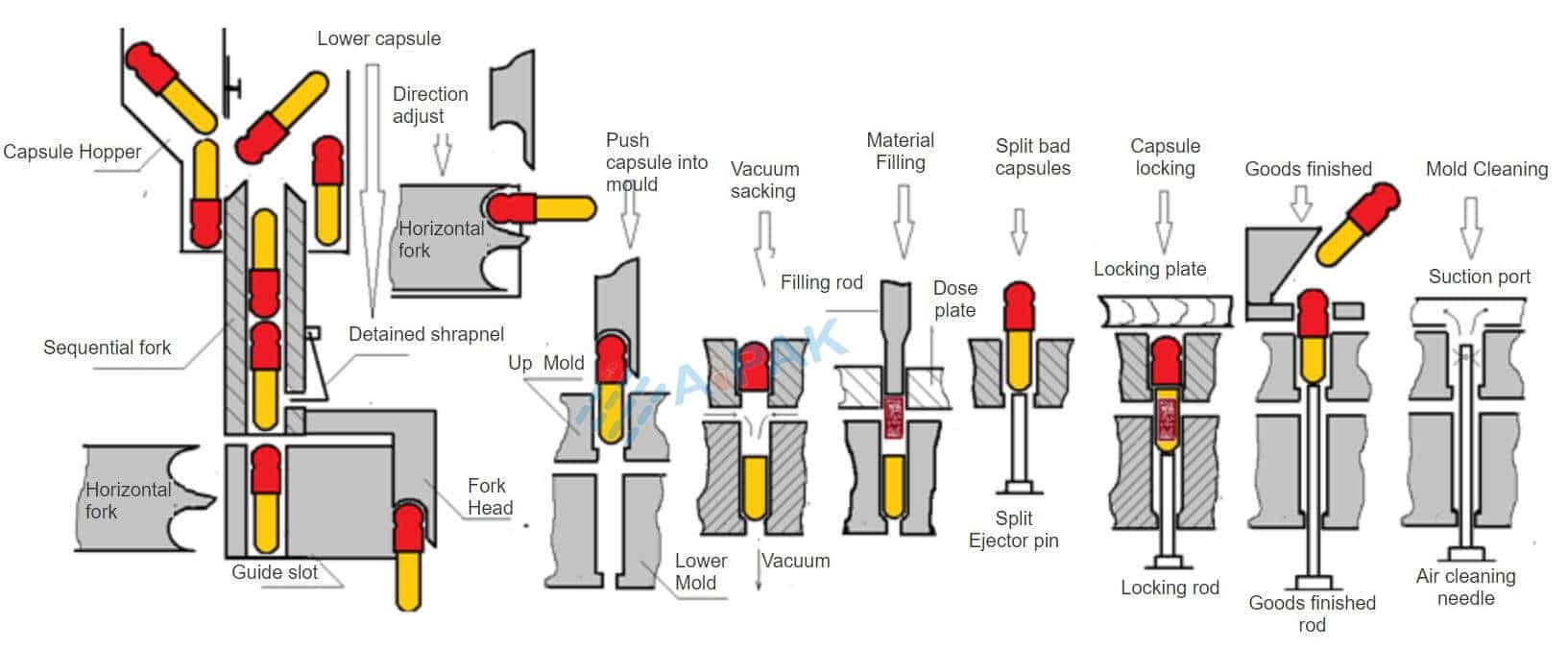

On the other hand professional capsule fillers are used in pharmaceutical industries at large scale production with high efficiency. However for the scope of this article Ill focus mainly on the dosator type capsule filling machines. Once the capsule separation is done the cap and the body are transferred to their respective stations.

Personal capsule filling machines is for small scale production and utilization. Find deals on capsule machine 0 on Amazon. They fill gas directly using a booster pump similar to how pressure liquid filling machines function.

Read customer reviews find best sellers. After rectification the capsule tray is moved to the capsule filling station and the caps and bodies of the capsule are separated using a vacuum divider. In stock ready to ship.

Automatic capsule filling machine working principle. You can adjust the plunger volume to make sure that the filling quantity is as per your requirements. Natural gas coal gas nitrogen and carbon dioxide are the principal filling materials.

This can be classified as liquid pressure filling which means the liquid flows into the bottle based on its own weight. During the operation the capsules in the charging hopper at the first station are. Working Principle of A Capsule Filling Machine.

In the capsule hop per the hollow capsule the main board moves up and down the capsule into. This can be classified as liquid pressure filling which means the liquid flows into the bottle based on its own weight. Ad Browse through 75 Used New Filler Powder Capsule Machines.

Automatic Capsule Filling Machine High Speed Capsule Filler

Hard Shell Capsule Filling Machines Basicmedical Key

Automatic Capsule Filling Machine Working Principle Ipharmachine

Capsule Filling Machine Fully Automatic Capsule Filling Process Working Animation Project Youtube

Tamping Pin Capsule Filling Machine Vs Dosator Type Capsule Filling Machine Saintytec

Semi Automatic Capsule Filling Machine Saintytec

Working Principle Of Dosator Type Capsule Filling Machine To Filling Powder Into Low Fill Weight Capsules

6 Stations You Must Know To Improve The Filling Quality Of Automatic Capsule Filling Machine Aipak

Working Principle Of Dosator Type Capsule Filling Machine To Filling Powder Into Low Fill Weight Capsules

Powder Filling Drug Absorption Pharmacological Sciences

Tamping Pin Type Capsule Filling Machine Working Principle

Automatic Capsule Filling Machine Working Principle Ipharmachine

Automatic Capsule Filling Machine Capsule Filling Machine Your Best Online Resource About Capsule Fillers

Automatic Capsule Filling Machine High Speed Capsule Filler

Filling Machines Their Working Principles

Capsule Filling Machine The Blueprint Guide Saintyco

10 Powerful Benefits Of Saintyco Dosator Capsule Filling Machine Saintytec